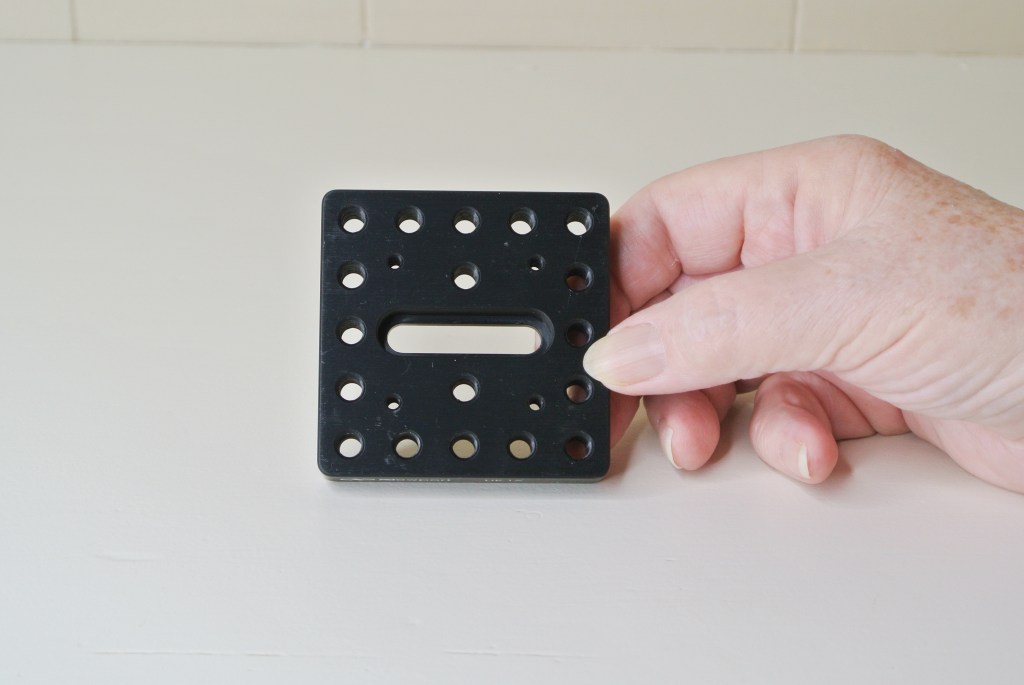

Just 2 photos to give a general idea of the form of the Newport Universal Baseplate.

In this post we review the MKS-Newport “UP-1A Universal Baseplate.” This is another very useful item to have in your lab. It has applications for testing, measurements, and for tooling. We purchased this product from MKS-Newport at the normal retail price.

Sometimes the pattern of holes on an optical breadboard simply do not work well for your tooling or experiment. In other cases you might not have access to any breadboard. Here is another inexpensive part from Newport which can help to address these situations.

Newport’s model UP-1A Universal Baseplate is a helpful part to have in your opto-mechanical bag of tricks. This item is a small square machined aluminum plate with multiple tapped holes and a slot which is located in the center. It is normally supplied with a matte black surface finish.

It is 2.56″ by 2.56″ and it is about 7/16″ thick. It has an array of 18 through holes tapped with 1/4-20 threads, and 4 holes with #6-32 threads. It also has a central slot which is counterbored, to accept a quarter-20 screw and will clear the head of a socket head cap screw. We will discuss that slot in just a bit.

The UP-1A Universal Baseplate has five 1/4-20 tapped holes along each side of the plate. (The holes in each corner of this plate will count for two sides.) Thus, there are a total of 16 threaded holes around the sides, and these are all spaced on 0.5″ centers. There are two additional 1/4-20 tapped holes in the interior, spaced on 1″ centers, on either side of the slot. That’s a total of 18 holes with 1/4-20 threads through this plate. There are also four holes provided with #6-32 threads spaced on what would be the corners of a 1.25″ square pattern, centered on the plate. Newport describes these holes as being useful for mounting their 40 mm x 40 mm stages. (These items are not described here.)

The Universal Baseplate can be used in a generic way to mount parts for tooling. However, the feature of this design which makes this plate so useful is its central slot. By using a single quarter-20 socket head cap screw to retain the plate to a breadboard, then sliding and rotating the UP-1A as needed before tightening that screw, you can provide a pattern of holes in an arbitrary orientation to the holes in the breadboard. This gives you more flexibility for mounting components than the breadboard does by itself. If you must work without a standard breadboard, you can make the same adjustments on any flat surface when mounting the Universal Baseplate. In this way, you can use this Universal Baseplate without a regular breadboard to provide some quarter-20 tapped holes in various orientations.

This simple but clever design allows an experimenter to move a mounted component around in rotation and (some) translation relative to other components. This freedom of movement can be useful in situations where you might not have established a rigorous spatial design for the equipment you are using, and you are thus searching for the optimal arrangement. It saves a lot of time.

You might wonder why this plate has outside dimensions of 2.56″ by 2.56″. That is part of a clever design. The outside dimensions of this plate are actually 65 mm x 65 mm. This makes the UP-1A Universal Baseplate compatible with the Newport Goniometric stages and their Pitch and Yaw stages, and other devices which also have a 65 mm outside dimension.

Some photos of this Baseplate will be provided in the next post.

END

In this post, we describe MKS-Newport’s model “CB-2 Construction Plates.” Newport designates these parts with their nomenclature as CB-2 Construction Plates, 2.5″ x 3.5″, 2 pieces, 1/4-20.

This product consists of two separate but identical aluminum plates, each of which is called a CB-2, and also includes two 1/4-20 socket head cap screws, usually made of stainless steel. We purchased this product from MKS-Newport at the regular retail price.

We quote a description of this product directly from Newport’s catalog: (Begin quote) The CB-2 Construction Base is a two-piece design that can be used as a bracket or a base. The base has plenty of tapped holes on all the surfaces as well as clearance holes and slots for 1/4-20 screws. Combine all three elements to construct rigid optical assemblies quickly and easily. (end quote)

The two plates supplied with this product are identical, so we will describe just one of them in detail. This design allows you to use the two plates separately, if that suits your application. They can be assembled together in several ways, as a single device. The CB-2 Plate has the form of a rectangular machined aluminum part.

This Plate from Newport is part of their line of bases. It’s designed to be attached to an optical breadboard or any other part, and has tapped holes on its surfaces so the user can attach other components to it. It is versatile enough to construct rigid optical assemblies without additional machining to the CB-2 itself. Your other components may be custom made. Or, you can assemble these two plates together to make a bracket or other device.

It has outside dimensions of 3.5″ length by 2.5″ width, with a thickness of slightly less than 0.5″. When we measured this sample with an engineer’s caliper, we got the following approximate dims:

3.500″ at the center of the plate, 3.502″ at one end, and 3.502″ at the opposite end for the length; and 2.502″ at the center, 2.501″ at one end, and 2.502″ at the opposite end for the width. We measured the thickness of this plate to be from 2.489″ to 2.490″. (These values are likely within the range of measurement accuracy using a caliper.)

This plate has four counterbored slots to accept quarter-20 socket head cap screws. The two shorter slots are spaced on 1″ centers, and the two longer slots are spaced on 2″ centers. This design means the plate can easily be attached to an optical breadboard having a grid of holes using 1″ spacing. You could use the two slotted holes with 1″ spacing or the two slots with 2″ spacing, and hit the hole pattern in a typical breadboard. The two plates together (minus screws) weighed just under nine (9) ounces.

The two plates in this product can be used separately or together in various ways, by assembling them, which is the reason they include two quarter-20 screws as part of the product.

Each plate has eleven tapped-through holes for quarter-20 screws on the large top surface. The four holes located at the corners of the plate are counterbored clearance holes which allow 1/4-20 socket head cap screws to be installed through each of them, by simply inserting a screw from the counterbored side.

When using this plate as a base, it allows you to attach a component on the top side using a quarter-20 screw inserted from the bottom side. When used as a base, you need only use one of the plates. This means you have the other plate to use as another base or for other purposes in the lab. The counterbored clearance holes at the corners of the plates are useful when making a right angle bracket. Note, there are two ways you can easily combine the plates to fabricate a right angle bracket. The resulting difference just determines where the vertical plate is located relative to the horizontal plate. You can also assemble it and just turn that assembly around to get the result you wish. As another example, you could drill out and counterbore two holes in one of the plates, then assemble the two to create a bracket which is “T”-shaped. Of course you can attach your own custom plate to one of the CB-2 plates, if that is a better result for your application.

This is another Newport product which is convenient and ideal to use with the other parts from their construction series. Of course this base/bracket can be used in many ways with your own equipment for tooling or testing purposes. When assembled to form a bracket, these plates provide a fairly rigid and sturdy component which can be readily used for optical testing applications as well as for custom tooling for assembly and fabrication of small parts. The resulting bracket’s effectiveness may depend upon how heavy your workpiece is going to be.

You could use two (or more) of these assembled brackets to suppkort a larger or heavier workpiece. There are other ways to make a bracket using this product, depending upon your specific application. Often it’s easier or less expensive to use these COTS parts for your application than to order custom designed parts from your machine shop. An engineer or technician could be rewarded by experimenting with these plates for a little while to discover other ways to use the CB-2 Construction Plates.

Some photos of this product will be located in a following post!

End