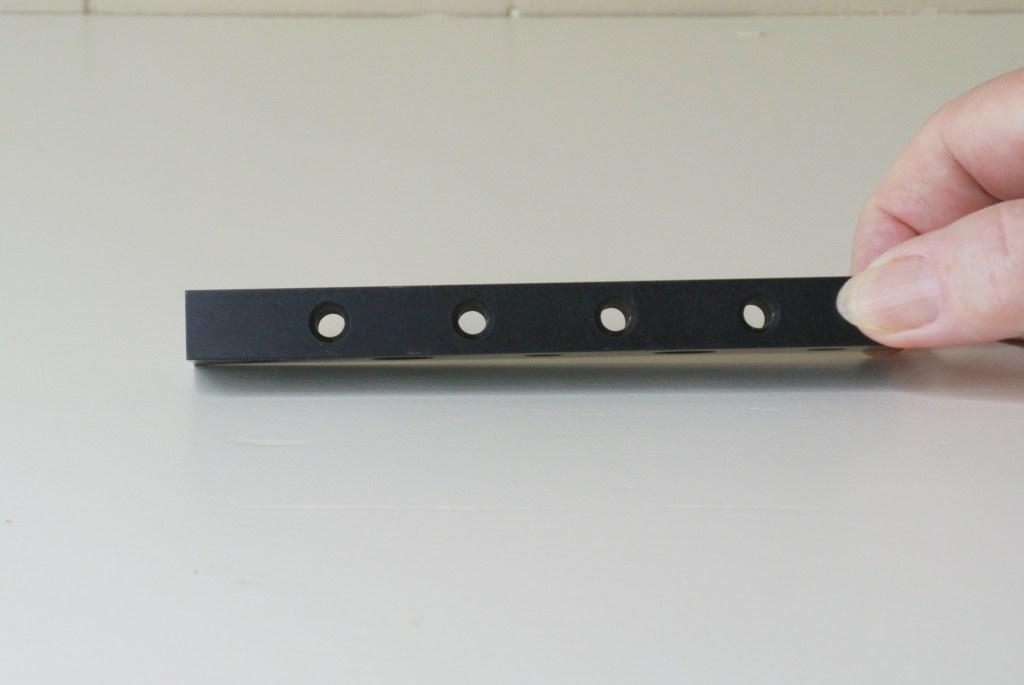

Some photos of the Newport Construction Rail

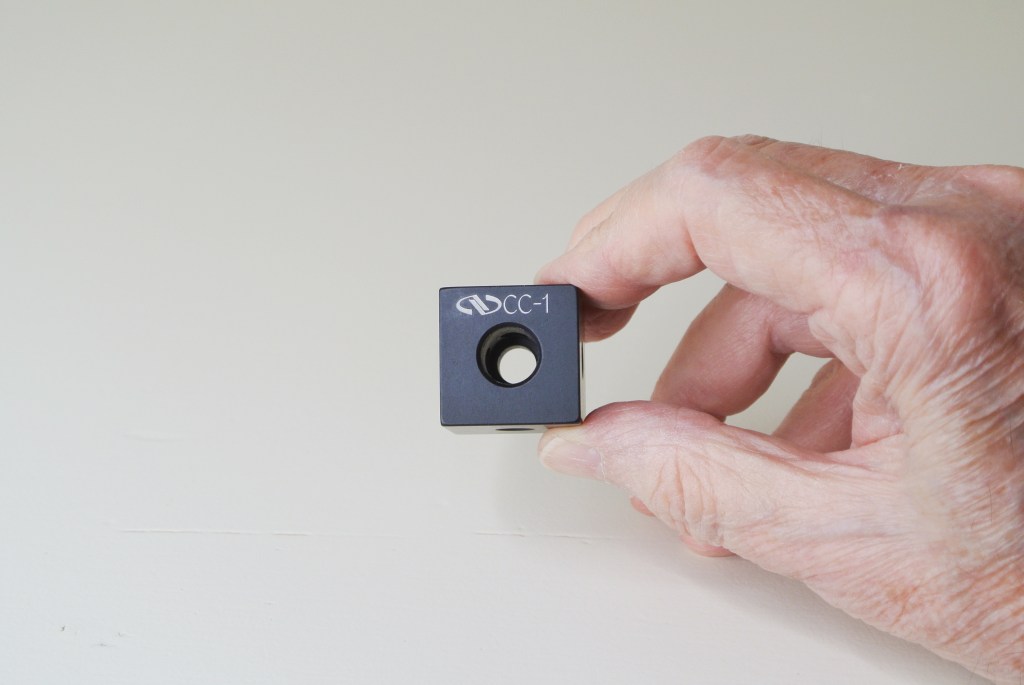

Some photos of the Newport Construction Cube

In this blog, we discuss the Newport Construction Cube. Newport designates this part by their nomenclature “CC-1″ Construction Cube, 1″x1”, 1/4-20. This is a machined cube made from aluminum which contains 1/4-20 tapped holes and a clearance hole. It is usually provided with a matte blackened surface.

The Newport CC-1 Construction Cube is made such that it presents six orthogonal faces, being a cube. Four of the faces have one 1/4-20 tapped hole in the center of each face. The remaining two faces of the cube have respectively one clearance hole for a quarter-20 screw and opposite that, one hole counterbored to accept the head of a quarter-20 cap screw. Thus, a 1/4-20 socket head cap screw can be inserted through the cube allowing the user to attach the cube to another external surface.

This design allows the user to attach this cube to another part with a quarter-20 socket head cap screw, where the head of the fastener fits inside the cavity of the cube, out of the way. Then you will have four 1/4-20 tapped holes (in four quadrants) available for other uses. The Construction Cube is simple but quite versatile.

It can be used by itself or attached to your own custom components to construct tooling. When attached with a single 1/4-20 socket head cap screw, it provides a sturdy, rigid component for mounting other parts. It’s especially useful when used with other parts from the Newport construction series.

One note about attaching this cube. With a standard quarter-20 socket head cap screw in the clearance hole, the head of the screw limits the length of screws you may attach to any of the four tapped holes. If instead, you use a low-profile-head type screw, and these are readily available from commercial sources, then a quarter-20 screw inserted into the side of the cube may be a bit longer.

Here are a few examples of really simple ways we used the Construction Cube at work:

1. We used the cube as a simple stop block.

2. We made a simplified adjustable stop block using a quarter-20 cup-point setscrew on one side and a nut to lock the setscrew in place after the desired stop position was set.

3. Two cubes were attached together with one screw to make a spacer for a tooling application.

4. We attached a cube to a construction rail to provide an offset attachment point for another component which we did not wish to attach directly to that rail.

5. Two rails were set parallel with one or 2 cubes used to provide a one inch separation between those rails.

6. Cubes were used to support a flat plate above a breadboard.

Obviously, there are many possible ways to use the cubes in the lab with applications limited only by your imagination. You may want to keep a bunch of these cubes in your assembly parts cabinet.

End

In this post we shall examine the Newport Construction Rail. This is a rectangular aluminum rail with several 1/4-20 tapped holes and two clearance holes for a 1/4″ fastener, with counterbored clearance for the round heads of cap screws. MKS-Newport specifies this product by their nomenclature, “CR-1″ Construction Rail, 1″ x 5”, 1/4-20. Next we will describe these in detail.

Incidently, the rails I will be reviewing are the Revision 2 of the CR-1. This Construction Rail is machined from a solid piece of aluminum. Overall it is a rectangular aluminum part with several holes, some of which are tapped with 1/4-20 machine threads. We did a quick measurement with an engineer’s steel rule which indicated that it is 5″ long, about 1″ wide, and a bit under 1/2″ thick. The part has two clearance holes for a 1/4″ fastener, spaced 2″ apart and about 1.5″ from each end of the rail. It has three each, 1/4-20 tapped through holes in the 1″ wide face. It has four 1/4-20 tapped through holes in the 1/2″ wide face, and also has one 1/4-20 tapped hole in each end of the rail. It normally is supplied with a matte black finish.

The holes are tapped fully through the body of the rail, except for the holes in each end. This is a useful feature if your application requires installing a long screw through the body of the rail where you want it to protrude from the other side for some attachment purpose. As for the two clearance holes, their counterbores are machined so that the head of a standard quarter-20 socket head cap screw will fit within the rail, so the head of that screw is flush with the surface. As for the two holes in the ends (one in each end) of the rail, a standard quarter-20 screw will enter the holes for about 8 and 1/2 turns, if there is no screw located in the last hole in the perpendicular face. If there is a screw in that last hole, then the end screw will enter for about 6 turns, which should be adequate contact for fastening strength for a quarter-20 threaded machine screw.

The three tapped holes in the largest face of the rail are spaced 2″ apart from each other, with the middle hole in the center of the rail. The four tapped holes in the top and bottom of the rail are spaced 1″ apart. When we measured this rail with a machinist’s digital caliper, we obtained the outside dimensions of the part to be:

Its length = 5.001″, its width = 1.002″, and the thickness = 0.490″.So these measured dimensions are very close to the manufacturer’s specified nominal dimensions for this part. That was satisfactory.

We weighed our sample of the Construction Rail with an analog scale just to satisfy curiosity. We obtained a weight of approx. 3.5 ounces.

The Newport Construction Rail was designed to be very adaptable to make various mechanical assemblies. It is just that. This rail can be attached to another rail (or two), or to one or more of the other components we shall review later. The rail is especially convenient for being used with the other construction components made by MKS-Newport.

It can be attached to a conventional optical breadboard surface in various ways. It can be used with other custom built parts you require, or it can be used as part of a custom testing application, as well as to build specialized assembly tooling. Its rectangular shape, strength, and multiple holes for fasteners make this an ideal component for constructing a wide variety of equipment, for optical or other sorts of engineering projects. As mentioned previously, we have experience using these construction rails in applications for building optical instrumentation on large telescopes and also for manufacturing tooling. The Newport Construction Rail has many possible uses in terms of making mechanical hardware in the laboratory as well as in manufacturing plant applications. We know this from actual experience, having actually used these rails to construct tooling in an optical lens manufacturing facility.

End